( image: FUJIKURA SHOTEN HP: http://www.take-fujikura.com/item/KL1583/ )

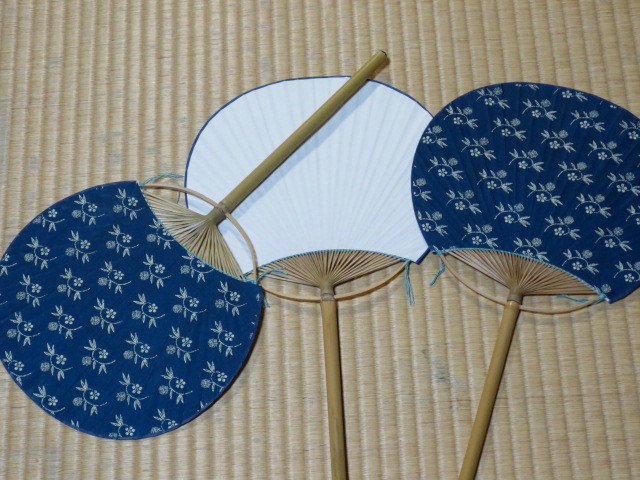

When you visit Japan in summer, you’ll see many people in kimono or yukata. Some of them may have a paper fan in their hand; this is the Japanese fan, which is called “Uchiwa”. They fan themselves by their uchiwa to feel the tranquil breeze and enjoy the summer all the more for the heat.

Many uchiwa have great Japanesque images on the surface; thus, they are so popular as souvenirs among foreign visitors these days. If you want something more special, however, let’s look at the historical and cultural one: Boshuu uchiwa.

What’s Boshuu uchiwa?

It’s pronounced like “Bow-shu Uchiwa”. Boshuu refers to the area of Japan, where was called “Awa-no-kuni” historically, in Kanto area.

It was 1780s that the people in Kanto area started making their uchiwa by themselves. Boshuu was a production area of bamboo, which is the material to make uchiwa, and started their own uchiwa industry in 1877; however, this didn’t last long. The culprit is the Great Kanto Earthquake.

The Earthquake wreaked havoc on many uchiwa warehouses, and many dealers moved to a nearby area, Funagata-machi, to keep on their business, where they were able to ship their products to Tokyo. This triggered the expansion of uchiwa made in Boshuu: now, Boshuu uchiwa got given birth to.

Funagata-macchi and its neighborhoods were a kind of fishing villages, so the men had to go out fishing; well, who conserved the culture and techniques of Boshuu uchiwa? Actually, it was their wives. They made uchiwa as a sideline while waiting for the return of their husband from the sea. The culture was carried on by their daughters and their grandchildren to be alive today.

How are Boshuu uchiwa made?

To be the material of Boshuu uchiwa, bamboo must be of high quality. They are harvested during October and January, for they are “bug-free” and firm in winter. As you know, bamboo is a very tall plant, but making uchiwa requires a certain thickness, which allows them to make only a few uchiwa out of a chop of bamboo. Including this “culling”, the procedure of making Boshuu uchiwa has more than 20 steps to make just one, all of which are manual. Doing all the procedure by oneself only can make 4 or 5 pieces of the uchiwa, so in many cases, some people get together to do this work at once.

The over 20 steps to make Boshuu uchiwa

First, they select and harvest the greatest bamboo from many others. In Japan, there are more than 600 species of bamboo, but the qualified one is just one which grows in the area. Then, they peel and wash the bamboo. An artisan says that the knack is to spin the bamboo with the knife fixed, not vice versa.

Then, they half-split and soften the “naked” bamboo. The un-split part is going to be the handle and the split part the fan. Following this, they put a hole in the handle to weave the split part to make it fan by a string. After this, they cut the un-split part into a certain length. Now, the end of the part has a hole (as you know, bamboo has a hole in the center). They fill it.

They pass another piece of bamboo through the hole on the handle and knot the string, which was used to make the fan part, to the ends of the piece. Now, they have an almost-uchiwa-like shape. They fix some warps of the frames of the fan and roast it to make them straighten.

And then, they put a piece of paper on both sides of the frames by glue. The extra length of the frames should be cut then. In addition to this, they put a thin piece of paper on the edge of the fan.

Now almost done. They put some whiting on the end of the handle to make it round and press the fan part by a presser to make it firm.

The various styles of Boshuu uchiwa

In Japan, Taisho era (1912-1926) saw the growing number of Boshuu uchiwa to be 7 millions. The Boshuu uchiwa in this era has much more frames and some of them are weaved to shape a butterfly and the like. In Showa era (1926-1989), Boshuu uchiwa became much more popular as a small gift and underwent its heyday. Some of them had an image of famous actors or actresses of the day on the fan. Yes, Boshuu uchiwa was also an advertising medium then. In Japan today, many musicians (especially those who are popular among young people) sell uchiwa that has their images on the faces and the fans (no pun intended) wave them to cheer up during their performance, you know.

The modern Boshuu uchiwa has mainly 4 kinds: Round one, egg-shaped one, long-handle one and large one. Plus, some people make a special one that has an ellipse-shaped fan. Of course, this shape is not good to create airflow to cool down your face and also not very portable. So what is this for?

Actually, some people make Boshuu uchiwa as an ornament for their house. They place the uchiwa in their entrance or Japanese-styled room. The large ellipse is sure enough to put a great image on it: it’s something like a picture! Uchiwa have two faces, of course, and you can enjoy two pictures by just one uchiwa.

If you are looking for something to perfect your Kimono style in the summer, you should have a handy uchiwa. You can feel the scent of bamboo on the wind then. On the other hand, in case that you want something Japanesque to embellish your room, it’s a great decision to consider ordering your unique uchiwa. Making your own Boshuu uchiwa may take long, but it deserves the result. Imagine your friends find a large uchiwa on your shelf like a bottled ship. “Hey, why do you have a fan here?” they ask, and you reply, “That’s not a fan. That is a uchiwa with great pictures on the faces, so I place it there as a ‘reversible’ picture.”

References

http://www.bosyu-uchiwa.com/

https://ja.wikipedia.org/wiki/%E6%88%BF%E5%B7%9E%E3%81%86%E3%81%A1%E3%82%8F

http://hinanosato.jp/uchiwa/hist.html

【日英対訳】日本の歴史100 100 Things on Japanese History

新版 東京の職人―技と誇りを伝える百人の匠たち